Transport frames

Basic information

Transport frames (TF) were determined both for careful and safety haulage, and economic storage of pipe/tube

bundles.

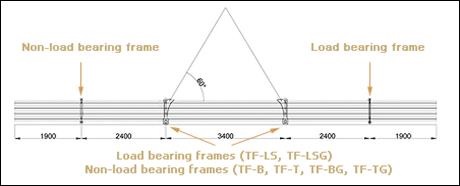

To establish pipe/tube bundle we need minimum 2 transport frame (number of frames within a bundle depends

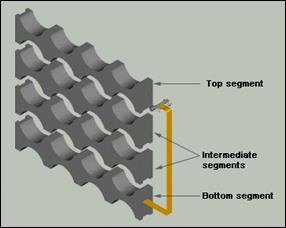

on the length of gathered pipes/tubes). Each of frames consists of rubber segments, reinforced with closed steel

rectangular

section and/or with a steel bar. Company PATREM PIPE TECHNOLOGIES s.r.o, as a rule recommends to its customers 4

transport

frames such a way, as depicted on below mentioned drawing of the pipe/tube bundle of 12 m length.

TF-LSG

TF-LSG system enables to hoist the overall bundle by means of yokes by the crane, unless the necessity to pass the

thru rope below such bundle. This is determined for safety pipe/tube bundle haulage of up to 7 t weight.

Whole this system was designed such a way, to enable both maritime, oversea and railway shipment.

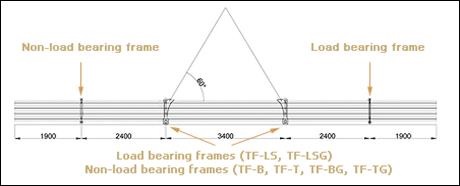

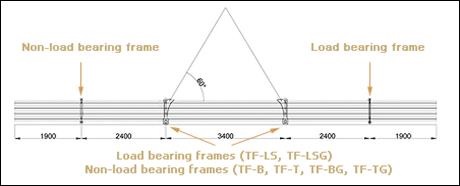

The whole system consists of two central load bearing frames and two end type non-load bearing ones, which maintain

the bundle shape and limit the pipe/tube bending in case of floor settlement.

Simulation of pipe/tube bundle, consisting of 2 load bearing and 2 non-load bearing frames.

Simulation of pipe/tube bundle, consisting of 2 load bearing and 2 non-load bearing frames.

Central Load Bearing Frame Consists of as Follows:

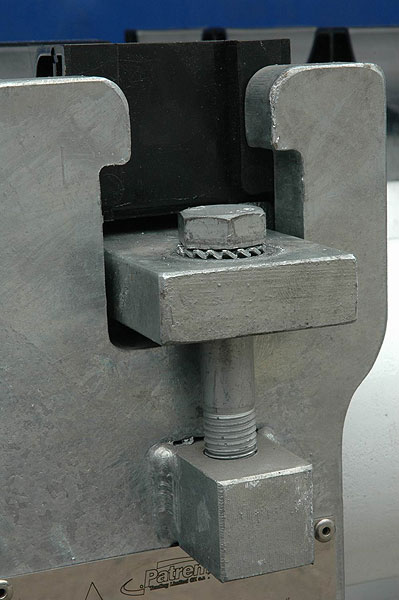

- 2 support plates made from steel. Holes for suspension yokes are situated in plated protected by applied

protective coating.

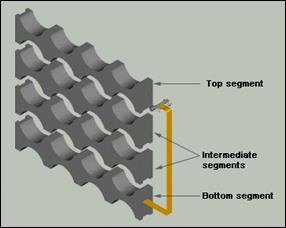

- Bottom segment made from square steel rod (the exposed parts of which are fitted with protective coating), being

its support element,

on which was made beds from a special composite material (rubber with admixture of additives) for pipe/tube

imposition. Position of

the bottom segment is ensured with grooves, enabling to the segment to settle into yokes of the support plates.

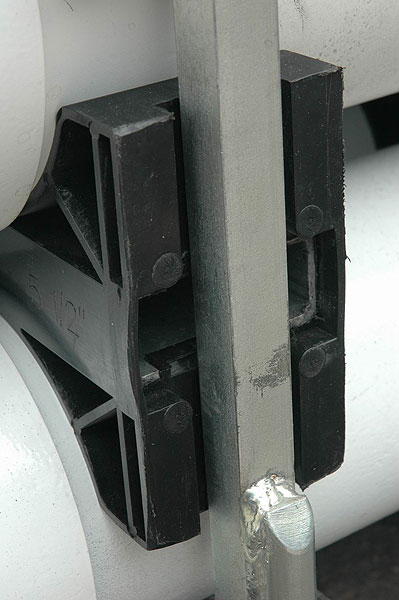

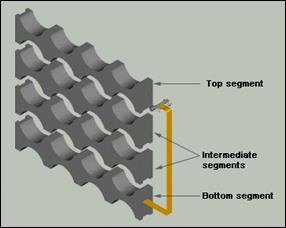

- Intermediate segments manufactured from a special composite material (rubber with admixture of additives) to the

core made from

zinc coated closed rectangular steel section, establishing the beds for pipe/tube imposition. Number of frame

segments differs

and depends on the size of bundled pipes/tubes (see below mentioned table). Side grooves within particular

central segments

ensure their frame axial position.

- Top segment consisting of zinc coated closed rectangular steel section, on which was made beds from a special

composite material

(rubber with admixture of additives) for imposition of the pipes/tubes. Steel rod (with applied protective

coating) is passed

thru closed rectangular steel section fitted with holes at both ends, thru which are during the assembly pulled

thru the screws,

fixing this steel rod to nuts in support plates. This ensures the stability of the overall bundle.

Support plates

Load bearing frame of TF-LSG type

Load bearing frame of TF-LSG type

Bottom segment

Bottom segment and its fixation in holes of the support plates

Bottom segment and its fixation in holes of the support plates

Intermediate segment

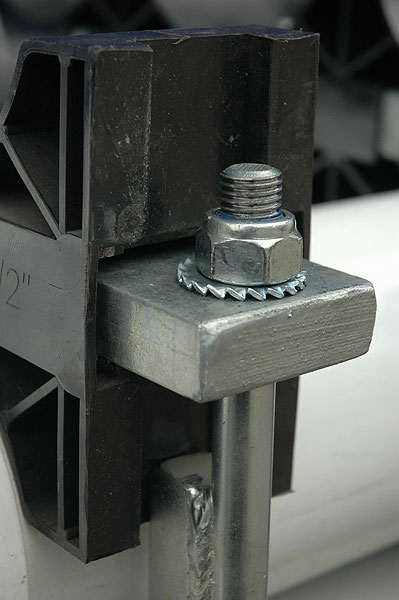

Ensuring the intermediate segments

Ensuring the intermediate segments

Top segment

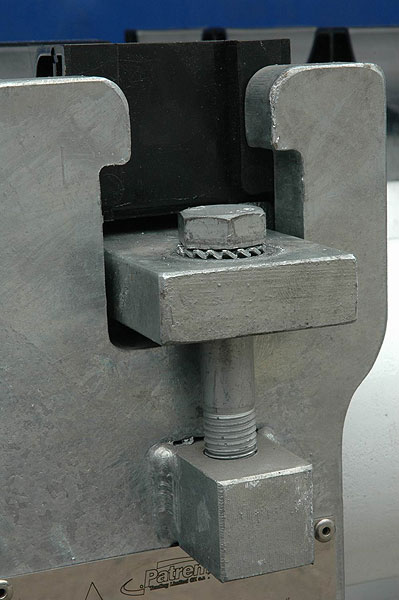

Top segment and its fixation to nuts located in support plates

Top segment and its fixation to nuts located in support plates

Boundary Non-load Bearing Frame Consists of as Follows:

- Bottom segment consisting of square steel rod (exposed steel parts are applied with a protective coating), on

which are beds for settling the pipes/tubes made from a special composite (rubber with admixture of additives).

Holes were done at both ends of the square steel rod for gripping the pull out rods.

- Intermediate segments, which are the same like the intermediate segments of the load bearing frames.

- Top segments consisting of zinc coated closed rectangular steel rolled section, on which were established beds

for pipe/tube settlement made from a special composite material (rubber with admixture of additives). Steel rod

(with applied protective coating) is poked thru closed rectangular steel section fitted at both ends with holes,

thru which are poked the screws of pull out rods, serving for pushing up the entire segment to the bottom one,

which ensures the stability of the overall bundle.

- Pull out rods, which are anchored in the bottom segment thru the "T" shaped bottom end, central rectangular part

establishes the guidance of intermediate segments and the screw situated in the upper part serves for pulling

the top segment up.

Transport frames of TF-LSG type are manufactured for following dimensions of pipes/tubes:

|

Outside diameter

|

Pipes per bundle

|

Pipes per segment

|

Bundle dimension

in mm (width x height)

|

|

60 mm / 2

3/8"

|

56

|

8

|

800 x 768

|

|

73 mm / 2

7/8"

|

42

|

7

|

830 x 813

|

|

89 mm / 3

1/2"

|

30

|

6

|

830 x 794

|

| 102 mm / 4"

|

20

|

5

|

830 x 711

|

|

114 mm / 4

1/2"

|

20

|

5

|

830 x 759

|

|

4

1/2" - drill pipes

|

16

|

4

|

830 x 811

|

| 127 mm / 5"

|

16

|

4

|

830 x 811

|

|

140 mm / 5

1/2"

|

16

|

4

|

830 x 863

|

|

168 mm / 6

5/8"

|

9

|

3

|

830 x 771

|

| 178 mm / 7"

|

9

|

3

|

830 x 801

|

| 178 mm / 7"

|

8

|

4

|

940 x 587

|

| 193 mm / 7

5/8"

|

9

|

3

|

830 x 801

|

| 193 mm / 7

5/8"

|

8

|

4

|

940 x 605

|

| 219 mm / 8

5/8"

|

6

|

3

|

940 x 689

|

| 245 mm / 9

5/8"

|

6

|

3

|

940 x 786

|

| 273 mm / 10

3/4"

|

4

|

2

|

830 x 800

|

| 273 mm / 10

3/4"

|

4

|

2

|

940 x 800

|

| 340 mm / 13

3/8"

|

4

|

2

|

940 x 976

|

Storage Height and Loading of TF-LSG

Storage height for pipe/tube bundles in case of application the transport frames of the TF-LSG system must be

adapted to stability and loading capacity of the subsoil, haulage procedure, and the strength of bound pipes/tubes.

Maximum load of the bottom segment within the frame is of 10 tons, that is why the load of pipe/tube bundle

consisting of two load bearing and two non-load bearing frames must not exceed 40 tons.

Testing of Load Bearing Frames of TF-LSG

All support elements of the TF-LSG - 2 frames consist of a support plate, together with the steel rod of the bottom

segment - are tested and inspected from the safety reasons such a way, to meet international standards. Tested parts

of the frame are marked with the label and confirmed thru the certificate.

Labels confirming the testing of frames support parts.

Labels confirming the testing of frames support parts.

Testing of Load Bearing Frames of Both TF-LS and TF-LSG

Testing of Load Bearing Frames of Both TF-LS and TF-LSG

|